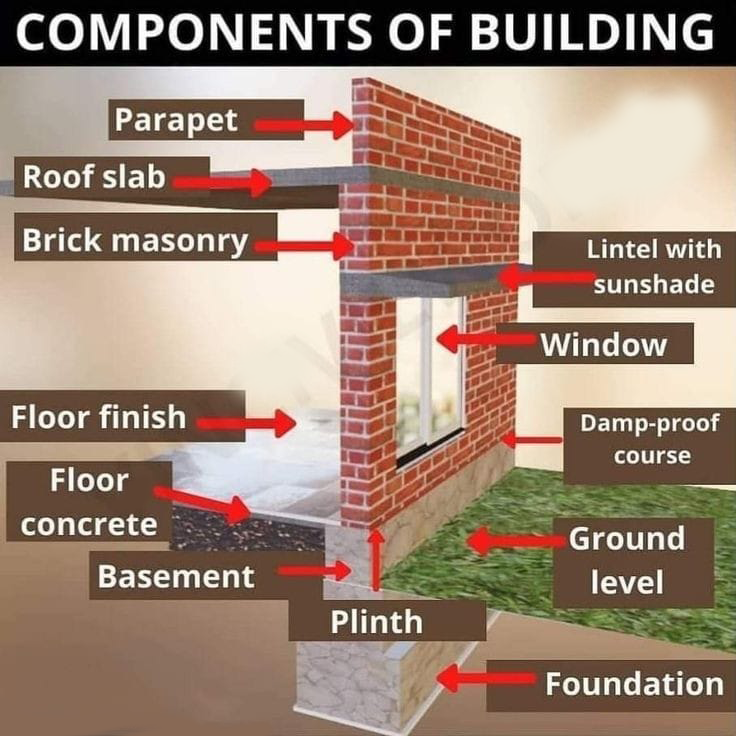

Essential Components of RCC Building

RCC building is currently the most popular building in Nepal. RCC is one of the sophisticated technology ever discovered on building

technology. A lot of new innovations are still going on RCC. Engineers will

know in detail about RCC technology in detail.

If you want to construct a RCC building with least supervision of engineers, you would like to understand about the basic aspects of RCC building. We list here some of the most essential components of RCC building that you should know while being ready to construct a small house of your dream.

Ground Level

Ground Level is also called the Original Ground Level. This

is the level of the land upon which you are constructing a building. This level

holds its importance during planning stage. Your engineer must elevate the

plinth level of your building above 1.5 feet or 2 feet above ground level.

Sometimes, it can go even more, but it can’t come down to a foot.

Plinth Level

Plinth Level is that level above the ground level which

separates the substructure with Superstructure. At the plinth level, there are

tie beams and damp proof course is applied at this level. This level separates

the earth element with the building element.

Superstructure

All the building construction works that are done above the

plinth level is called superstructure. This will include the ground floor too.

The load of the superstructure in the RCC building will be born by the columns.

The boundary between the super structure and substructure is Damp Proof Course

layer.

Substructure

All the building construction works that are done below the

plinth level including the plinth beam and the damp proof course above the

plinth beam is called substructure. The function of the substructure is to

transfer the load coming from the column to the foundation and to increase the

stiffness of the building.

Damp Proof Course

Damp proof course is the layer which actually separates the

superstructure and substructure. Damp proof course is a 3-inches-max thick

layer that is usually applied as a mixture of thick mortar and Waterproof. A

thin layer of hot bitumen can also act as a good Damp proof course. Damp proof

course will effectively prevent the seepage making the ground floor walls of

your building damp.

Window and Doors

In a RCC structure, doors and windows are placed after casting the structure. The walls, doors and windows do not participate in load dissipation or do not come in the load path of the building. Lightweight doors and windows will therefore decrease the cost of your RCC building without compromising the security of the building too much.

Floor Concrete

The concrete which is cast in order to make the floor is

called floor concrete. It is done after ramming the earth and putting brick

soling above it. The ramming should be done at 15% moisture content for most

effective compaction. Floor concrete

will make the surface finished and it will also level the ground so that the

tenants will feel secured from underground animals and will have comfortable

living. Not only ground floor, floor concreting is done at every floor.

Typically, the thickness of floor concrete at ground floor is higher than that

at the top floors. Another term for floor concrete is PCC and the ratio of PCC

should be 1:2:4.

Floor Finish

The layer which comes after the floor concrete is called

Floor finish. This is done at every floor. As floor concrete levels the

surface, floor finish will give the final look to the ground or slab upon which

you will rest. The typical weight of the floor finish is 1 kN/m2 for slabs.

Basement

The basement comes right above the foundation. It is a part

of substructure. Basement is often used as parking space. The space below

basement floor PCC and floor finish is the foundation layer itself. There could

be various foundations like mat foundation, combined footing or single footing,

depending on the results of structural analysis.

Brick Masonry

Brick masonry is the laying of brick in the substructure and

superstructure of the building. The mortar ratio for brick masonry should be at

least 1:6 or depending upon specifications. Brick masonry doesn’t transfer the

load in case of RCC structure. Crack is often a problem in Brick masonry but

there are various measures to all kinds of crack which you can read over here. Brick

masonry is important in substructure to prevent the cracks from propagating.